Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

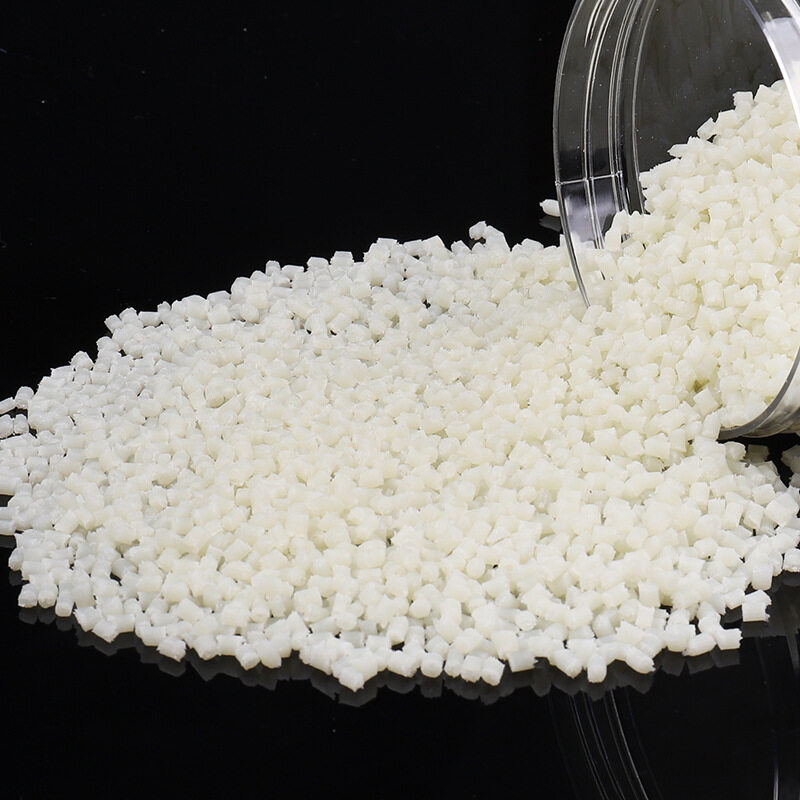

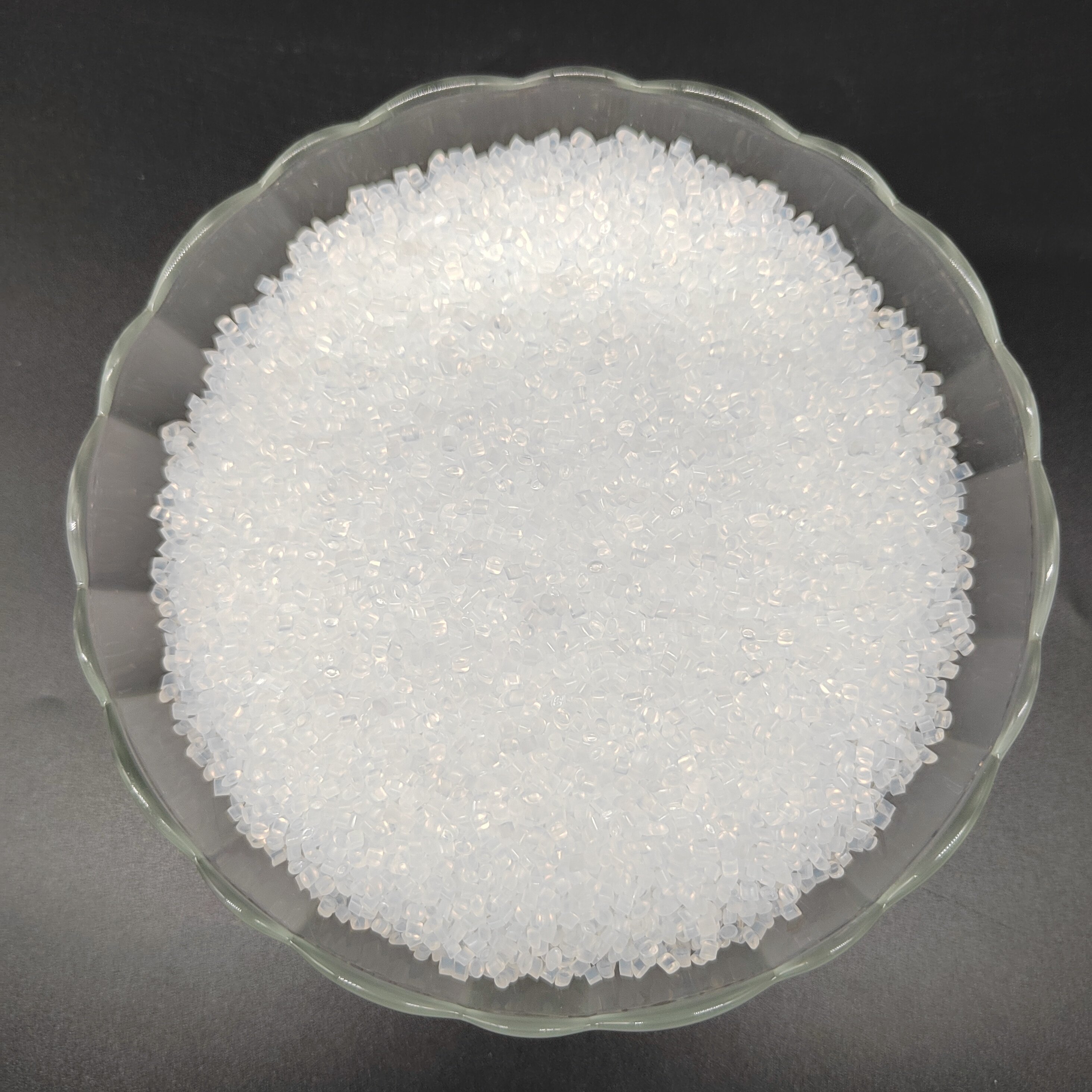

PA66 F01400MC

UL94 1.6mm V2

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PA66 F01400MC

| 拓扑新材料 名称: PA66 TOPONEW 牌号: F01400MC NC |

||||

| 产品简介 Product Description | 主要应用 Applications | |||

| ·PA66 | ·注塑成型 Injection molding | |||

| ·优异的耐热老化性能 Excellent heat stability | ·良好的机械性能Good mechanical properties balance | |||

| 性能 Properties |

测试标准 Test Method |

测试条件 Test Condition |

单位 Unit | 典型值 Typical Values |

| 物理性能 Physical properties | ||||

| 密度 Specific Gravity | ISO 1183 | 23℃ | g/cm3 | 1.15 |

| 机械性能 Mechanical properties | ||||

| 拉伸强度 Tensile Strength | ISO 527 | 50mm/min | MPa | 55 |

| 弯曲强度/Flexural Strength | ISO 178 | MPa | 75 | |

| 弯曲模量 Flexural Modulus | ISO 178 | 2mm/min | MPa | 2400 |

| 简支梁缺口冲击强度 Charpy Notched Impact Strength |

ISO 179-1eA | 23℃ | kJ/㎡ | 10.5 |

| 热性能 Thermal properties | ||||

| 热变形温度 Heat deflection temperature |

ISO 75 | 1.80MPa | ℃ | 165 |

| 其它性能 Other properties | ||||

| 相对漏电起痕指数(CTI) | IEC 60112 | 600 | ||

| 灼热丝耐燃性能/GWFI/GWIT | IEC 60695-2-13 | GWIT: 760/1.0 | PASS | |

| IEC 60695-2-12 | GWFI: 960/1.0 | PASS | ||

| 阻燃性 Flammability | UL94 | 1.6mm | V2 | |

| 说明:以上数据是典型值,不是保证值。根据模具设计,例如浇口类型,浇口分布,浇口数量的不同,注塑工艺和制件厚 度的不同,测试结果会有波动。不同的颜色,测试结果也会有波动。在使用材料之前,请咨询拓扑新材料有限公司。 Note: The data above is typical value for reference, not guarantee value. The data will vary with tool design such as gate type , gate location, gate number, injection molding process and part thickness. The data will vary with different color as well. Prior to use the material,please consult with TOPO NEW MATERIAL CO.,LTD. |

||||

PA66, also known as Nylon 66, is a type of synthetic polymer that belongs to the family of polyamides. It is created from two monomers: hexamethylenediamine and adipic acid. The "66" in the name refers to the fact that each monomer has six carbon atoms.

PA66 is known for its high strength, toughness, and excellent wear resistance. It has a high melting point and is resistant to chemicals, abrasion, and impact. These properties make it suitable for a variety of applications.

One of the most common uses of PA66 is in the manufacturing of engineering plastics. It is used to make components for various industries, including automotive, electrical and electronics, industrial machinery, and consumer goods. Examples of PA66 applications include engine components, electrical connectors, gears, bearings, and structural parts.

The glass reinforced polyamide 66 (PA66) material holds immense significance in the automotive industry. With its exceptional mechanical properties and high heat resistance, PA66 has established itself as a top choice for manufacturing various automotive parts.

PA66 is a type of polyamide 66 polymer known for its excellent balance of strength and durability. Its structure consists of long chains of alternating hexamethylene diamine and adipic acid units, resulting in a highly stable and robust molecular composition.

The market for glass reinforced polyamide 66 has witnessed substantial growth in recent years due to its ability to enhance the performance and functionality of automotive components. The addition of glass fibers enhances the material's stiffness, strength, and impact resistance, making it ideal for critical applications in the automotive sector.

Automotive parts made from PA66, such as intake manifolds, radiator end tanks, oil pans, and engine covers, benefit from its superior mechanical properties, including high tensile strength and excellent chemical resistance. Additionally, its remarkable heat resistance enables these parts to withstand extreme temperatures, ensuring long-lasting performance in demanding automotive environments.

PA66 GF20/ PA66 GF30/ PA66 GF35/ PA66 GF40/ PA66 GF50

Download

-

PA66 F01400MC NC.pdf

Download PA66 F01400MC NC.pdf