Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

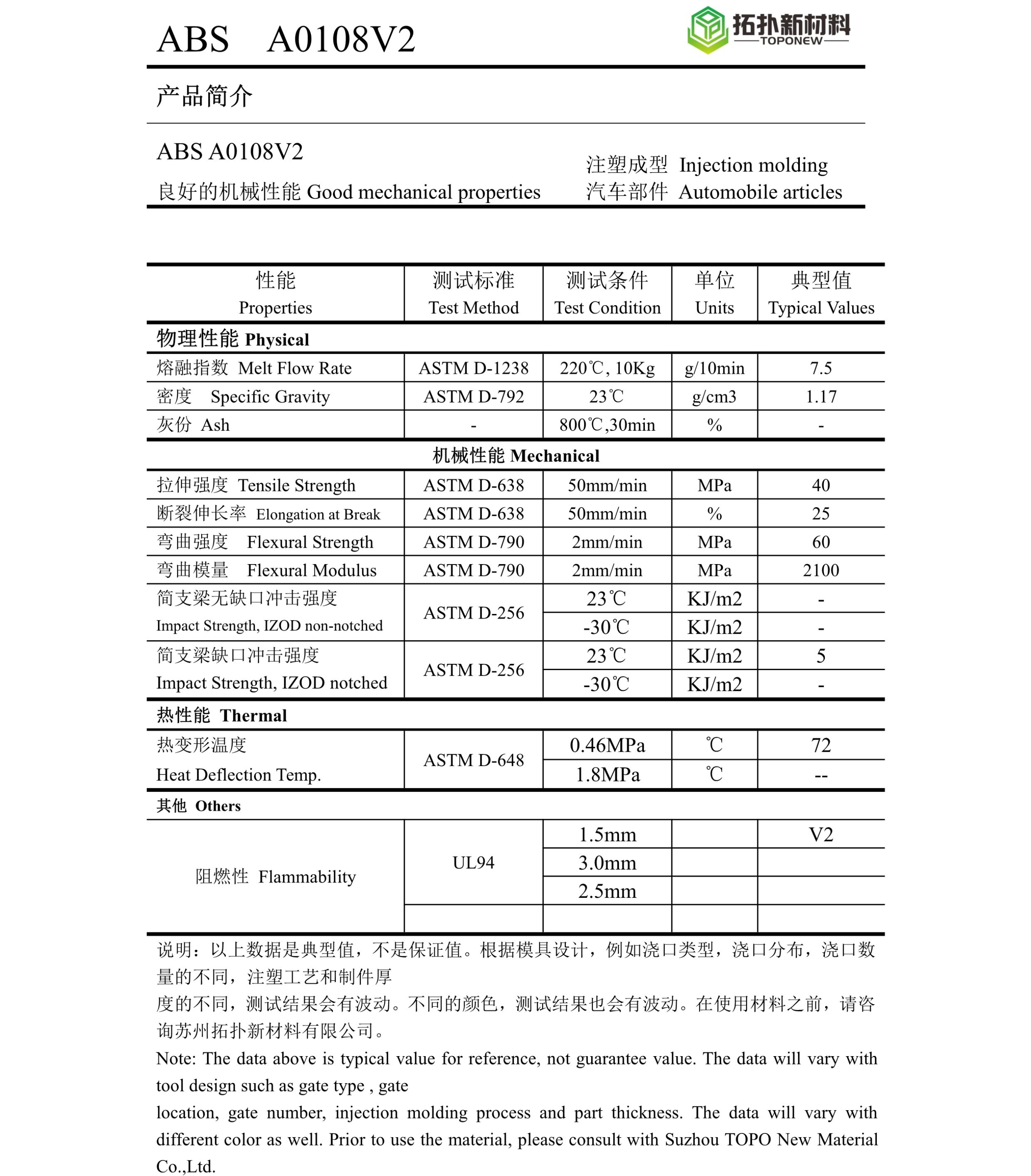

ABS A0108V2

MI: 7.5 g/10min

UL94 1.5mm V2

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

The Technical Data Sheet of ABS A0108V2

ABS Granule ABS Flame Retardant ABS Granules

Welcome to the world of plastic granules business! In this fast-paced industry, it is crucial to stay up-to-date with the latest trends and innovations. Today, we will be introducing you to ABS A0108V2 - a high-quality ABS granule that is setting new standards in the market.

ABS granules are widely used in various industries due to their exceptional properties. Acrylonitrile butadiene styrene (ABS) is a versatile thermoplastic polymer known for its excellent mechanical strength, impact resistance, and thermal stability. ABS A0108V2 in particular boasts a melt index (MI) of 7.5 g/10min, guaranteeing efficient processing and handling.

One of the standout features of ABS A0108V2 is its UL94 1.5mm V2 rating. This fire-resistant classification provides an added layer of safety in applications where flame retardancy is a necessary requirement. Whether it is in electrical enclosures, automotive components, or consumer goods, ABS A0108V2's V2 rating ensures enhanced fire protection.

The advantages of acrylonitrile butadiene styrene (ABS) as a material are numerous. Its high impact strength makes it capable of withstanding significant external forces without cracking or breaking. ABS is also known for its excellent dimensional stability, allowing it to retain its shape even in extreme temperatures. Furthermore, ABS exhibits excellent chemical resistance, making it suitable for environments where exposure to various substances is expected.

In summary, ABS A0108V2 is a standout product in the plastic granules business. With its impressive mechanical properties, UL94 1.5mm V2 fire-resistant rating, and the numerous advantages of acrylonitrile butadiene styrene (ABS), this ABS granule is the perfect choice for manufacturers seeking reliable, high-performance materials for their applications. Stay ahead of the competition and unlock the full potential of ABS A0108V2 for your next project.

Q & A

1. What is acrylonitrile butadiene styrene ABS?

Acrylonitrile butadiene styrene, commonly known as ABS, is a thermoplastic polymer that is widely used in various industries for its durability and strength. It is a hard and rigid material that combines the properties of three different monomers: acrylonitrile, butadiene, and styrene. ABS is known for its excellent impact resistance, high heat resistance, good dimensional stability, and chemical resistance. It is commonly used in applications such as automotive parts, consumer products, electrical enclosures, pipes, and fittings.

2.Acrylonitrile Butadiene Styrene advantages and disadvantages

Advantages of Acrylonitrile Butadiene Styrene (ABS):

Excellent impact resistance: ABS is known for its high impact resistance, making it suitable for applications where durability is critical.

High heat resistance: ABS has good heat resistance and can withstand temperatures up to approximately 80°C (176°F) without deforming.

Good dimensional stability: ABS exhibits minimal shrinkage during cooling, allowing for precise and accurate manufacturing.

Chemical resistance: ABS is resistant to many chemicals, including acids, alkalis, and oils, making it suitable for various industrial applications.

Easy to process: ABS can be easily molded into complex shapes and can be machined, drilled, and painted.

Disadvantages of Acrylonitrile Butadiene Styrene (ABS):

Poor weatherability: ABS has relatively poor resistance to weathering and can degrade when exposed to prolonged sunlight or UV radiation, resulting in yellowing or loss of mechanical properties over time.

Limited temperature resistance: While ABS can withstand moderate heat, it has a lower heat resistance compared to other engineering plastics like polycarbonate or polyethylene.

Warping and shrinkage: ABS has a tendency to warp or shrink during cooling, which can affect the dimensional accuracy of the finished product.

Potential for hazardous fumes: When ABS is heated or burned, it can release toxic fumes, including styrene, which can be harmful if inhaled. Adequate ventilation is necessary when working with ABS.

Poor resistance to some chemicals: While ABS has good resistance to many chemicals, it may not be suitable for applications involving strong solvents or certain aggressive chemicals. It is important to consider the specific chemical compatibility when selecting ABS for such applications.

It's worth noting that the advantages and disadvantages of ABS may vary depending on the specific application and requirements.

Download

-

ABS A0108V2.pdf

Download ABS A0108V2.pdf