Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

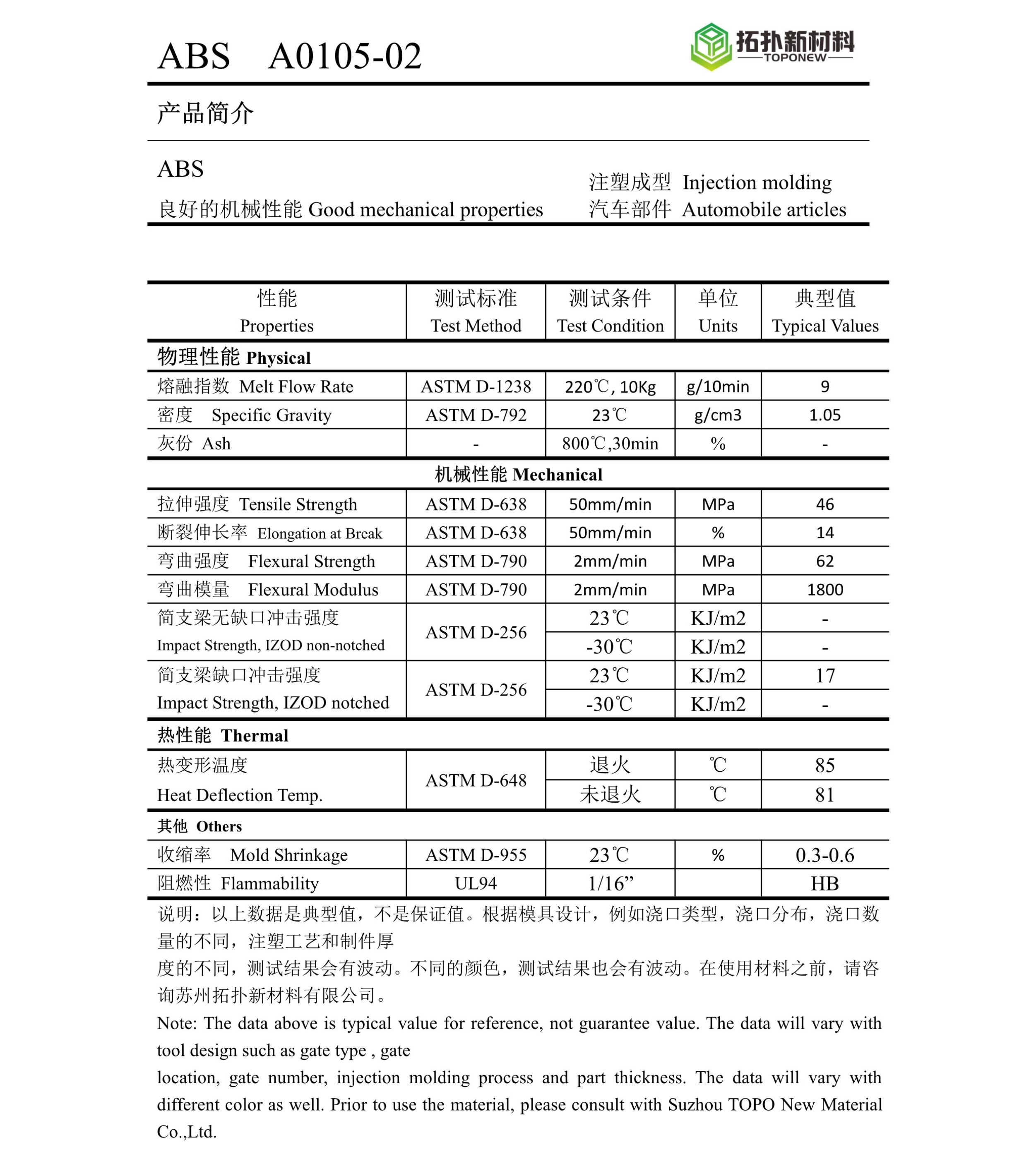

ABS A0105-02

MI: 9 g/10min

UL94 1.6mm HB

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

The Technical Data Sheet of ABS A0105-02

ABS A0105-02 is a highly flowable material with a melt index (MI) of 9 g/10min and a UL94 flame retardance rating of HB for a 1.6mm thickness. It is a toughened grade of ABS material.

Being highly flowable, ABS A0105-02 allows for easy and efficient molding processes. Its melt index value indicates its ability to flow and fill mold cavities effectively, resulting in smooth and uniform molded parts.

In terms of flame retardance, ABS A0105-02 has a UL94 rating of HB, which means it has a high resistance to flame spread and does not easily ignite or sustain a flame. This property adds an extra level of safety to applications where fire resistance is important.

Due to its toughened composition, ABS A0105-02 exhibits enhanced impact resistance and durability compared to standard ABS materials. It can withstand impact and mechanical stress, making it suitable for applications that require toughness and strength.

Overall, ABS A0105-02 is a highly flowable and toughened-grade ABS material that offers good moldability, flame retardance, and impact resistance. It is commonly used in various applications such as automotive parts, electrical enclosures, consumer electronics, and household appliances.

Download

-

ABS A0105-02.pdf

Download ABS A0105-02.pdf