Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

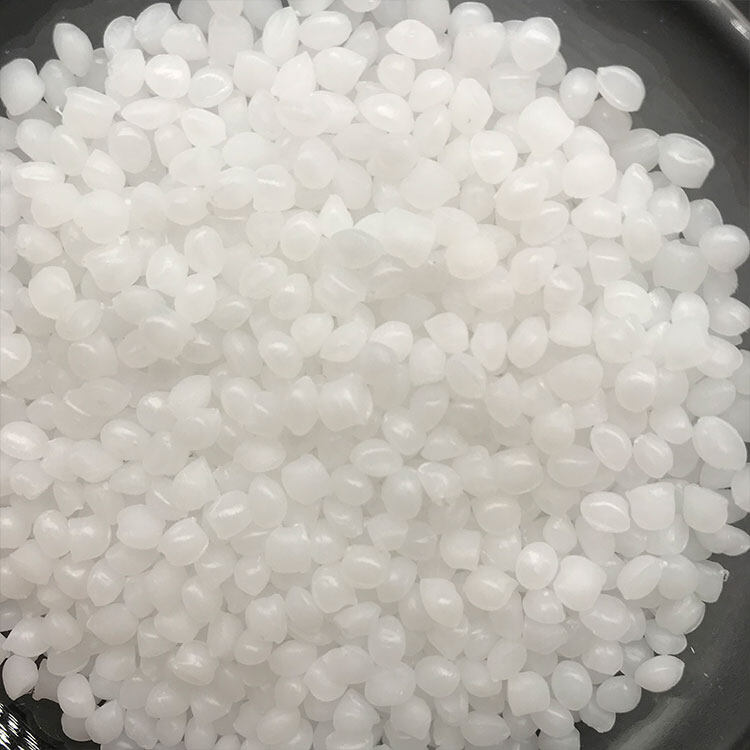

PP 20% Micro Glass Beads Filled TPH1120GFH

Wear Resistant, High Toughnes, High lmpact Resistant, Heat Resistant

20% Glass Beads Filled

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PP 20% Glass Beads Filled Material PP TPH1120GFH

Introducing our innovative product, PP (Polypropylene) filled with 20% glass microspheres. This remarkable material boasts a myriad of advantageous properties, making it a superior choice in various applications.

High Impact Resistance, Wear Resistance, Heat Resistance, and High Toughness are just a few of the remarkable characteristics of this composite material. Unlike traditional additives such as carbon black and glass fibers, glass microspheres offer unique benefits to automotive manufacturing.

Due to their spherical shape, glass microspheres provide transparency, exceptional compressive strength, and high thermal stability. Furthermore, they enhance mechanical stress under load, thereby improving overall performance.

With these exceptional qualities, PP engineered plastics reinforced with glass microspheres stand out as the optimal choice for optimizing costs and quality in automotive manufacturing. Choose innovation, choose durability, choose PP filled with 20% glass microspheres for your next project.

What is 30% glass filled polypropylene?

30% glass-filled polypropylene, often denoted as PP GF30, is a type of composite material where polypropylene (PP) is reinforced with 30% by weight of glass fibers. The addition of glass fibers enhances the mechanical properties of polypropylene, such as stiffness, strength, impact resistance, and dimensional stability.

PP GF30 exhibits improved strength and heat resistance compared to standard polypropylene. It is commonly used in applications where higher mechanical performance is required, such as in automotive parts, electrical components, industrial equipment, and consumer goods.

"PP glass" could imply a type of composite material where Polypropylene is enhanced with the addition of glass fibers to improve its mechanical properties.

What is the temperature range for glass filled polypropylene?

Glass-filled polypropylene, such as PP GF30 (30% glass fiber reinforced polypropylene), typically has an improved temperature resistance compared to unfilled polypropylene. The specific temperature range for glass-filled polypropylene can vary depending on the exact composition, processing method, and grade of the material.

In general, glass-filled polypropylene can withstand temperatures ranging from around -30°C to 120-150°C (-22°F to 248-302°F) depending on the specific formulation and the duration of exposure. Prolonged exposure to temperatures at the higher end of this range can lead to some degradation in mechanical properties.

For accurate and detailed information on the temperature range of a particular glass-filled polypropylene material, it is best to refer to the manufacturer's technical datasheet or consult with the supplier.

Download

-

PP TPH1120GFH.pdf

Download PP TPH1120GFH.pdf