Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

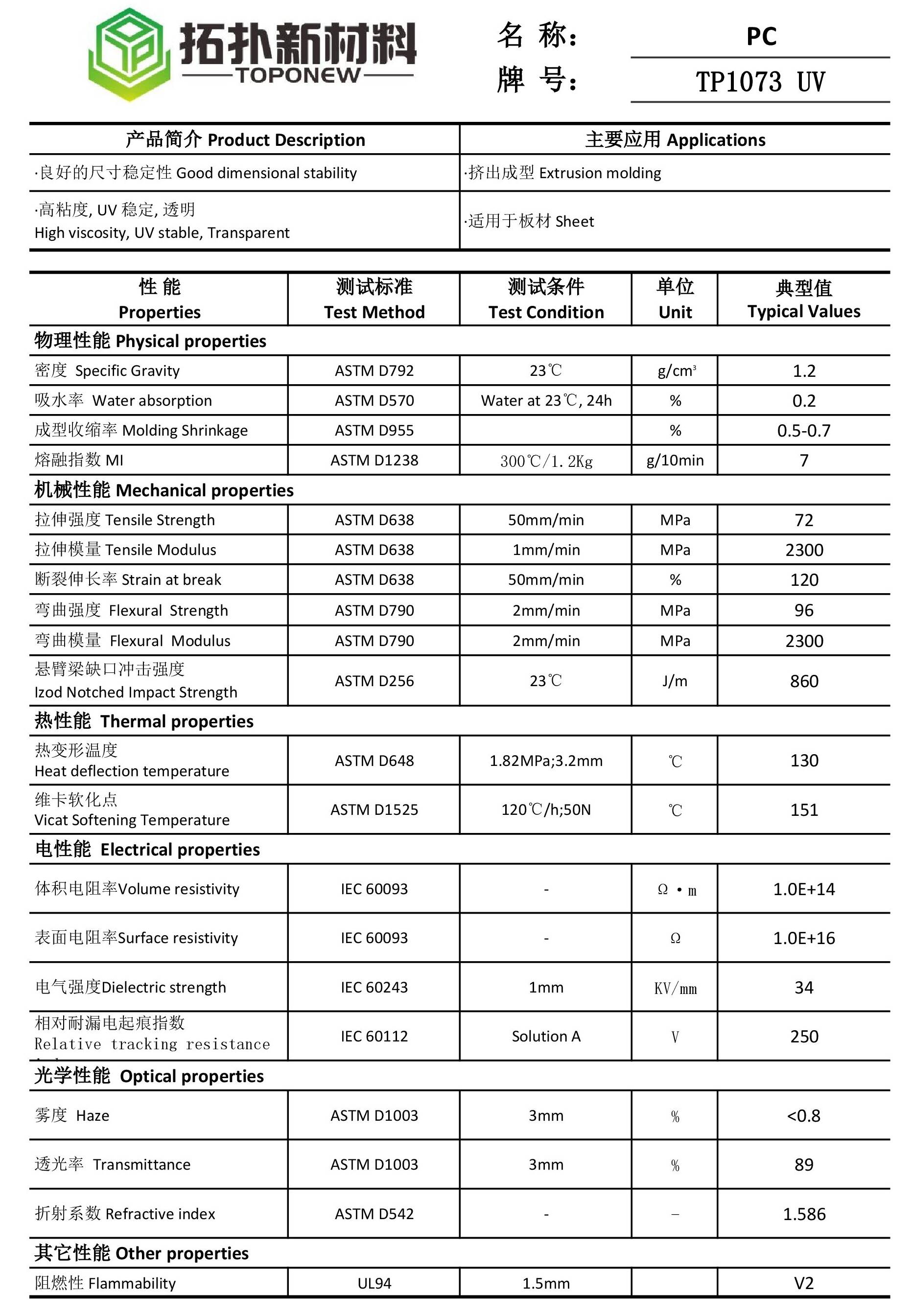

PC TP1073 UV

High viscosity, UV stable, Transparent

Extrusion molding

Sheet

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

- The Technical Data Sheet of PC TP1073 UV

PC TP1073 - a specialized material tailored for PC sheet applications. With high viscosity, UV stability, and exceptional clarity and transparency, PC Granules PC TP1073 offers superior properties for your projects. Its extrusion processing characteristics make it a top choice for achieving high-quality, durable PC sheet products.

PC sheets, or polycarbonate sheets, are typically manufactured through an extrusion process. Here's a general overview of how PC sheets are made:

-

Raw Material Selection: Polycarbonate resin is the primary raw material used in making PC sheets. The quality of the raw material affects the final properties of the sheet.

-

Extrusion:

- Mixing: The polycarbonate resin pellets are typically mixed with additives such as UV stabilizers or flame retardants based on the intended application.

- Melting: The mixed materials are then melted in an extruder under controlled temperature and pressure conditions to form a molten polymer.

-

Shaping:

- Die Design: The molten polymer is forced through a die that controls the thickness and width of the sheet.

- Cooling: The extruded sheet is then cooled using rollers or a cooling bath to solidify the material.

-

Cutting and Finishing:

- The solidified sheet is cut into desired lengths or rolls.

- The edges may be trimmed or processed further to achieve the desired finish.

-

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure the sheet meets specifications for thickness, clarity, strength, and other mechanical properties.

-

Optional Treatments: PC sheets can undergo additional processes such as surface coating for UV protection, anti-scratch coatings, or color tinting based on the specific requirements.

Overall, the extrusion process is key to producing PC sheets in various thicknesses, sizes, and finishes for a wide range of applications such as glazing, signage, roofing, and more.

Download

-

PC TP1073 UV.pdf

Download PC TP1073 UV.pdf