Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

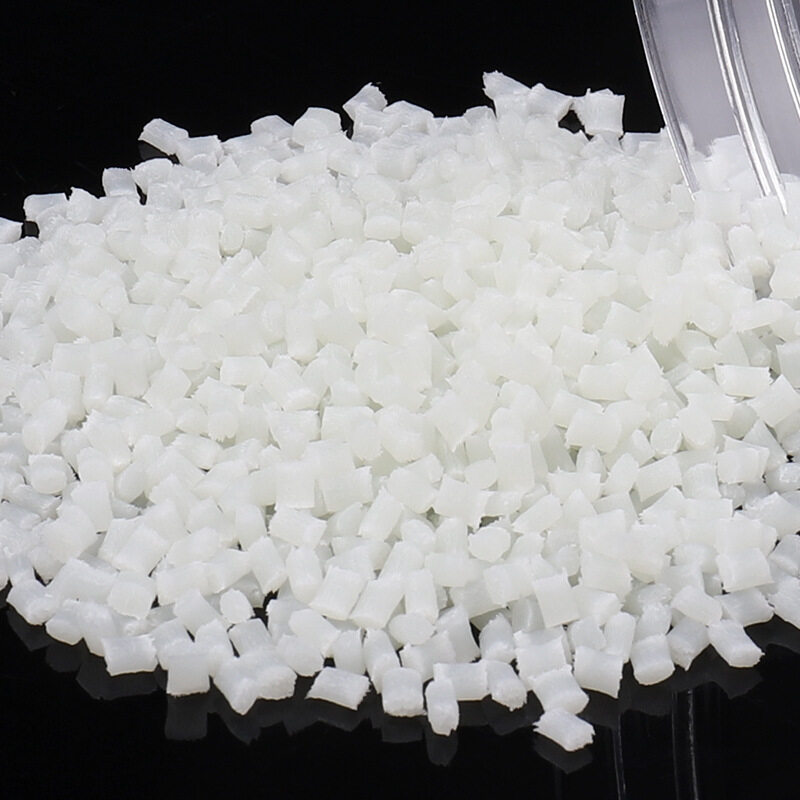

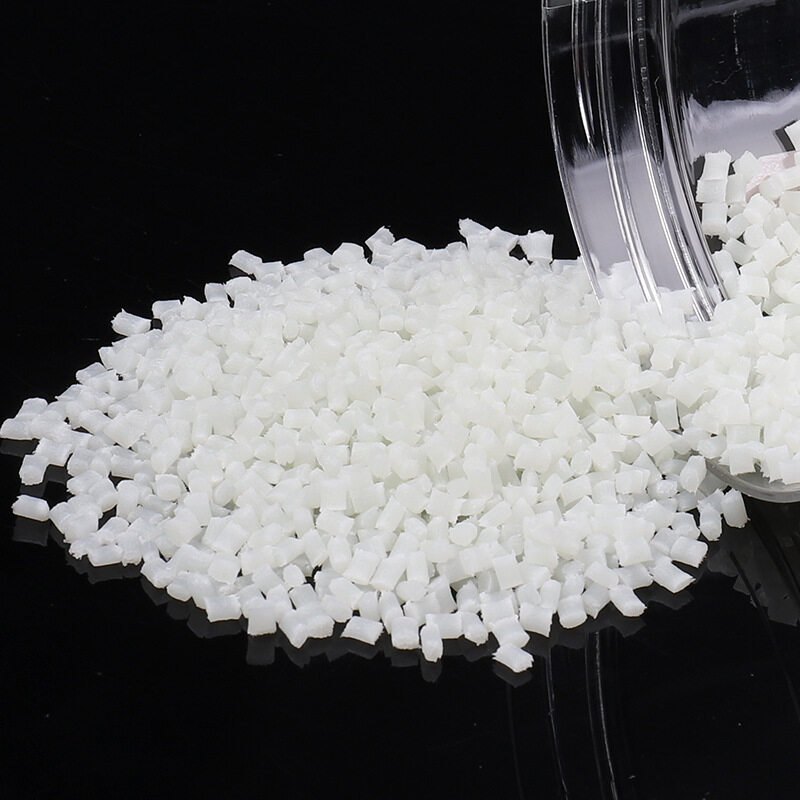

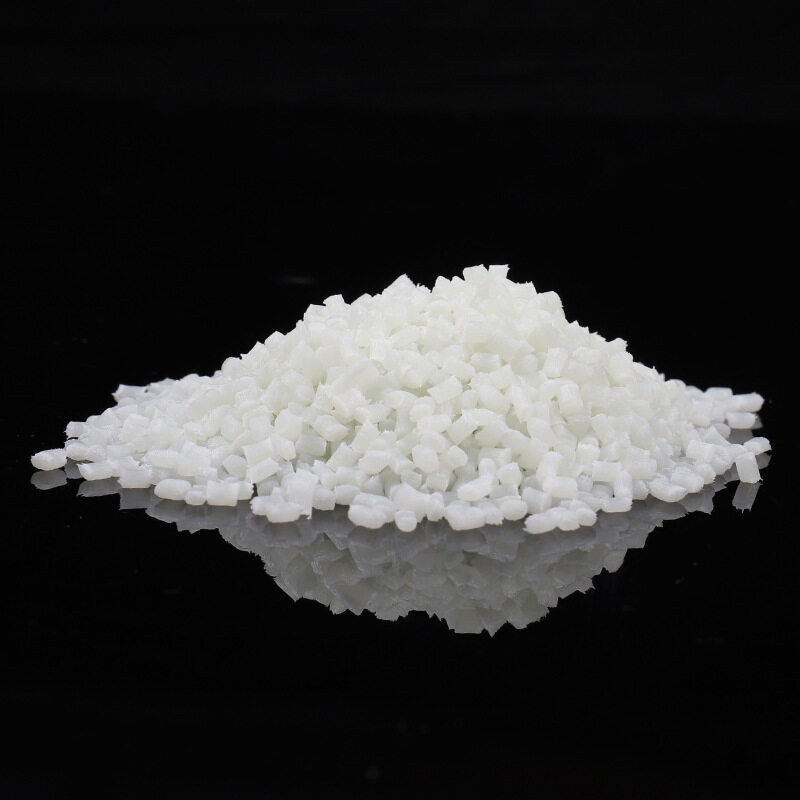

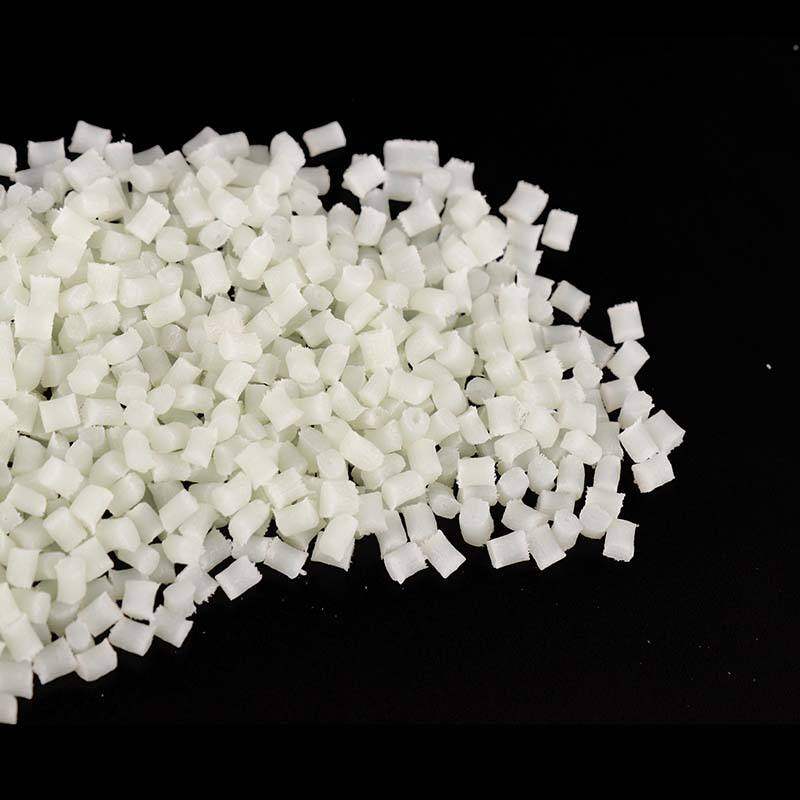

PA66 GF50 F0750

Glass Filled: 50%

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PA66 GF50 F0750

50% Glass Filled PA66 Nylon Plastic Resin

PA66 GF20/ PA66 GF30/ PA66 GF35/ PA66 GF40/ PA66 GF50

PA66 GF50, a high-performance polyamide material, is specifically designed for automotive applications. With a 50% glass fiber reinforcement, its significant strength and stiffness enhance the performance and durability of automotive parts. The material is known for its outstanding mechanical properties, such as high tensile strength and impact resistance, making it ideal for demanding automotive environments.

PA66 GF50 material's excellent dimensional stability and resistance to heat and chemicals make it suitable for various automotive components. Its superior temperature resistance allows for safe operation in high-temperature engine compartments without compromising structural integrity. Additionally, its resistance to wear and tear ensures long-lasting performance, even under challenging conditions.

Not only does PA66 GF50 offer exceptional mechanical and thermal properties, but it also provides advantages in terms of weight reduction. Its lightweight nature contributes to overall vehicle weight reduction, leading to improved fuel efficiency and lower emissions. This eco-friendly characteristic aligns perfectly with the automotive industry's growing emphasis on sustainability.

Furthermore, PA66 GF50 can be easily processed, allowing for efficient and cost-effective manufacturing of automotive parts. Its excellent flowability and moldability make it suitable for complex shapes and designs, ensuring a high degree of flexibility in production processes.

In summary, PA66 GF50 is a highly reliable and versatile material that meets the demanding requirements of automotive applications. Its exceptional mechanical properties, thermal stability, and lightweight advantages make it an optimal choice for automotive parts, ensuring long-lasting performance, fuel efficiency, and sustainability.

Download

-

PA66 GF50.pdf

Download PA66 GF50.pdf