Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

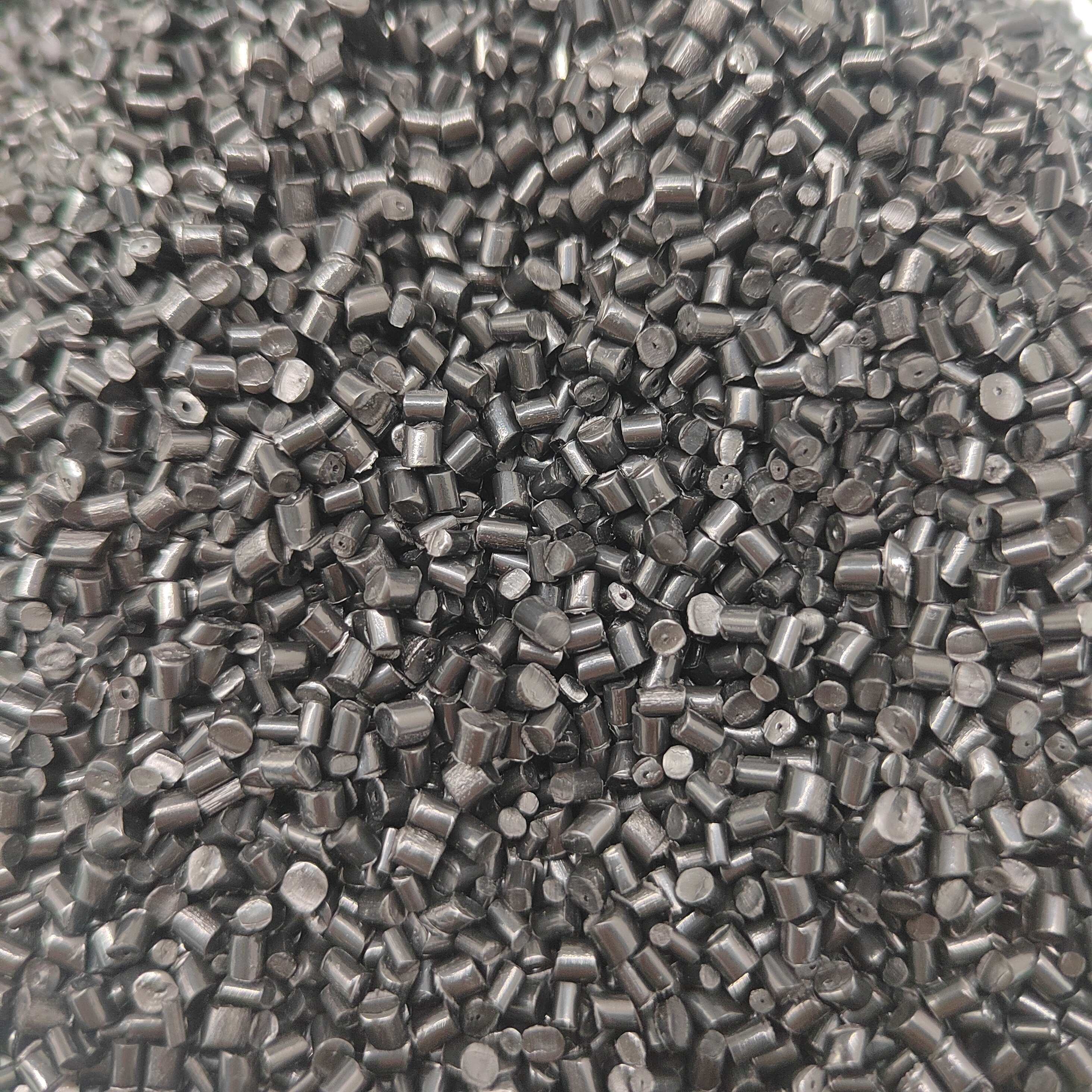

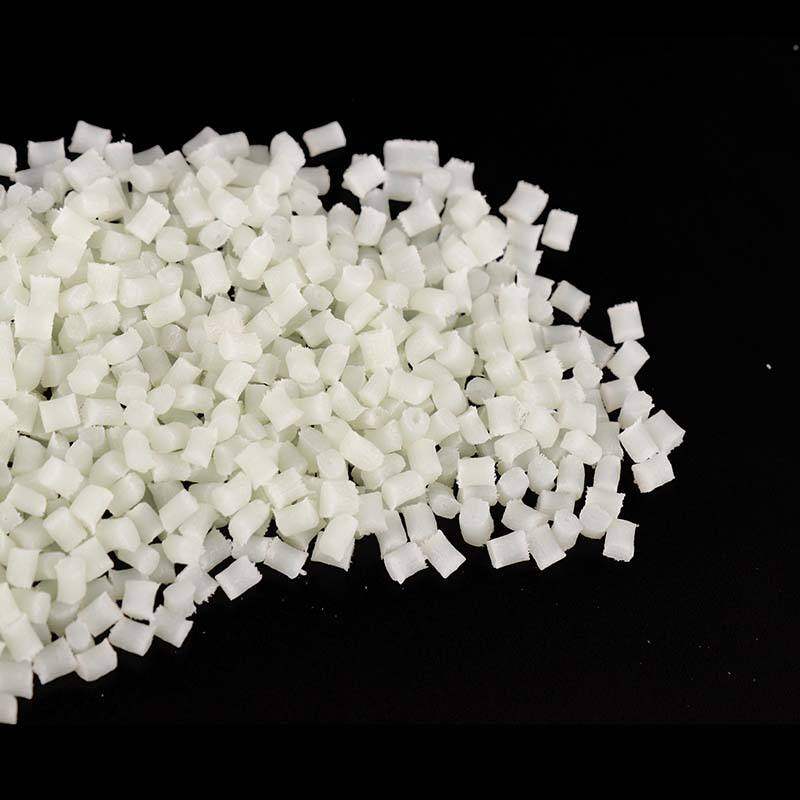

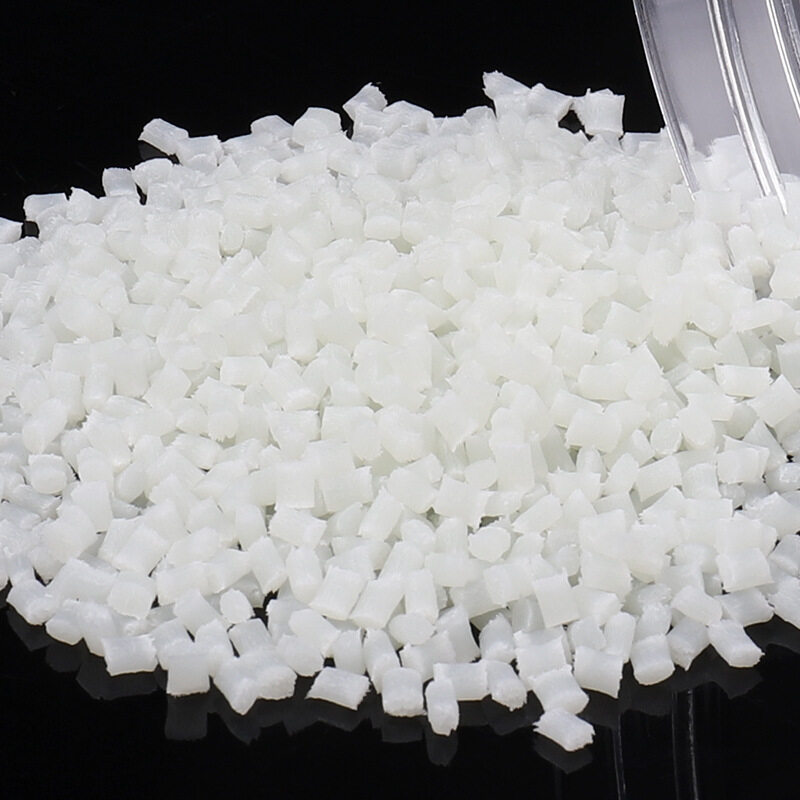

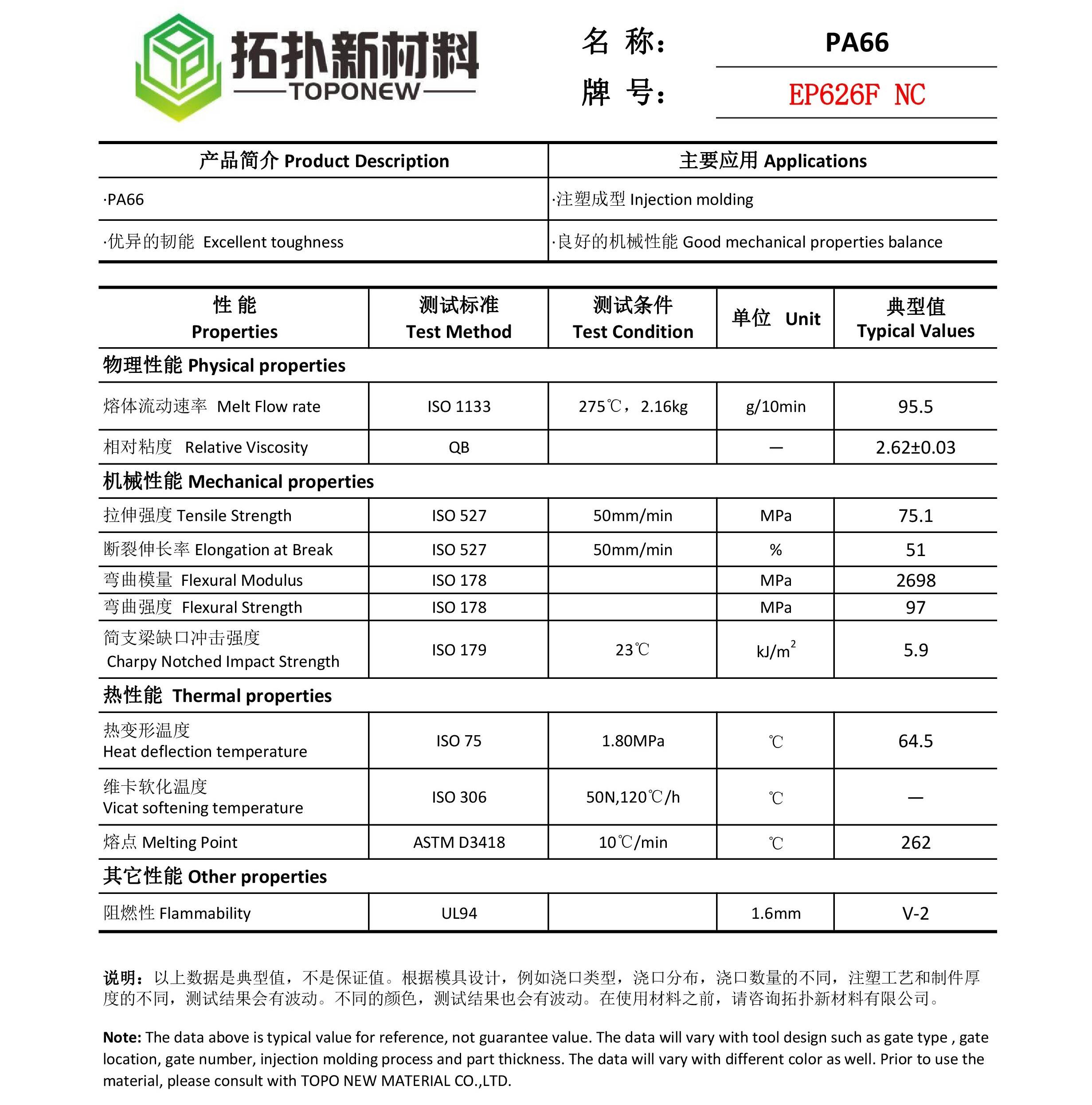

PA66 EP626F

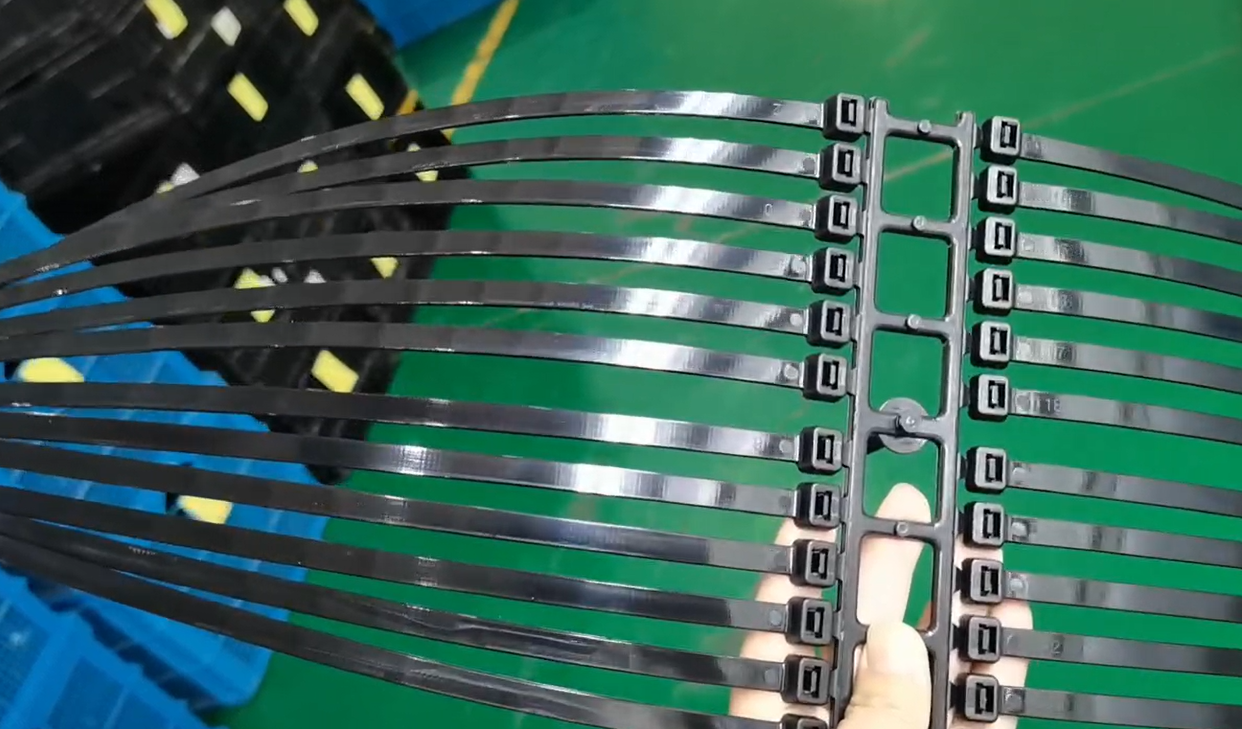

Suitable for plastic cable tie production

Excellent toughness

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PA66 EP626F

In the realm of plastic granules, finding the perfect raw material for manufacturing cable ties can be a crucial task. One material that has proven its excellence in this domain is PA66 EP626F - a remarkable polyamide 66 granule with exceptional properties and superior quality. Boasting a wide range of attributes tailored for cable tie production, PA66 EP626F stands out as an ideal choice for manufacturers looking to craft robust and reliable cable ties.

Raw Material for Plastic Granules: As a raw material for plastic granules, PA66 EP626F exhibits outstanding characteristics that set it apart from other options in the market. One of its key features is its high melting point, which allows for excellent melt flow and processability during the granule manufacturing stage. This ensures that the resulting granules possess a consistent and uniform quality, laying a solid foundation for the production of high-quality cable ties.

Polyamide 66 Properties: PA66 EP626F, being a variant of polyamide 66, inherits many of the advantageous properties associated with this versatile polymer. One of its notable properties is its exceptional tensile strength, with values reaching up to 500N.

PA66 EP626F, with its exceptional properties and high-quality characteristics, has solidified its position as the go-to raw material for manufacturing cable ties. Its remarkable tensile strength, flexibility, resistance to environmental factors, and excellent mechanical properties make it an ideal choice for creating robust and reliable cable ties. With PA66 EP626F, manufacturers can confidently produce cable ties that excel in performance and durability, meeting the diverse needs of industries such as electrical, telecommunications, and automotive. As the demand for reliable cable management solutions continues to grow, PA66 EP626F stands as a valuable ally for manufacturers seeking to provide high-quality cable ties that endure the test of time.

Download

-

PA66 EP626F.pdf

Download PA66 EP626F.pdf