Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

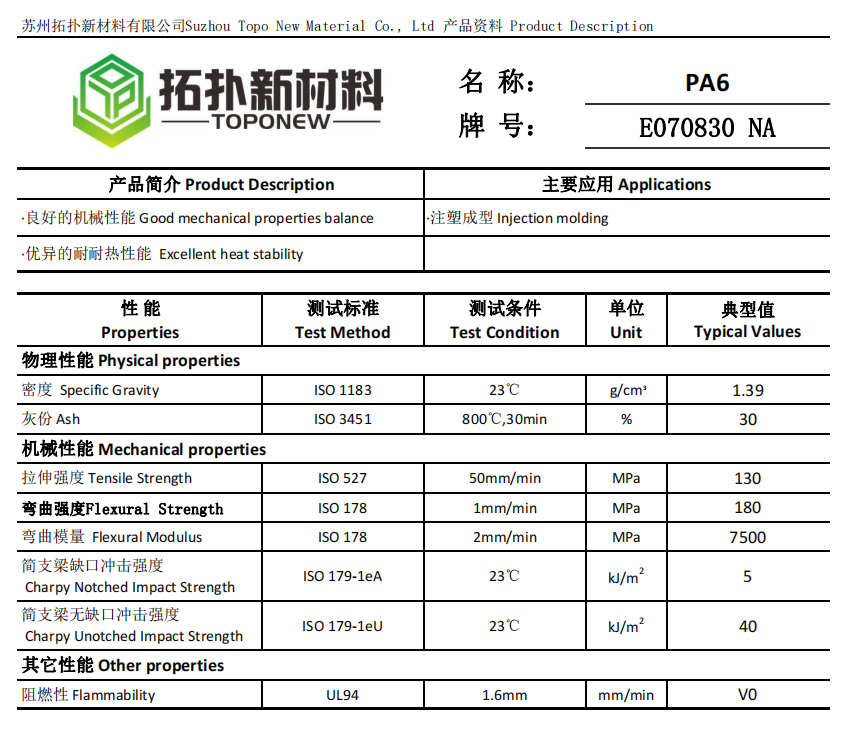

PA6 GF30 E070830WL

Glass Filled: 30%

UL94 1.6mm V0

Halogen Free Flame Retardant Nylon PA6 Granules

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of PA6 GF30 E070830WL

(Fr V0 PA6 Granule Resin PA6 Pellet Price Polyamide Nylon 6)

Nylon 6 30 GF Properties

The abbreviation "gf" stands for glass fiber, which is added to nylon 6 to enhance its mechanical strength and stiffness. Nylon 6 with 30% glass fiber reinforcement offers improved tensile strength, dimensional stability, and resistance to deformation. These properties make it an excellent choice for applications requiring enhanced structural integrity, such as automotive components, industrial equipment, and electrical enclosures.

PA6 GF30 Halogen Free Granules are a type of engineering plastic composite that consists of Polyamide 6 (PA6) as the base material and 30% glass fiber reinforcement. These granules are specifically formulated to provide enhanced mechanical properties, such as increased strength, stiffness, and heat resistance compared to regular PA6.

The term "halogen-free" implies that these granules do not contain halogens, which are chemical elements such as chlorine, fluorine, bromine, and iodine. Halogens are commonly used as flame retardants in various plastics, but their presence can lead to the release of toxic gases and corrosive fumes when the material is exposed to fire. In contrast, halogen-free formulations are designed to meet strict fire safety regulations while minimizing the environmental and health risks associated with halogen-based flame retardants.

PA6 GF30 containing halogen: https://www.toponew.com/products/pa6-compound/PA6-E070830YL

PA6 GF30 Halogen Free Granules are often utilized in applications where high strength, rigidity, and flame resistance are required. They are commonly used in automotive components, electrical connectors, industrial equipment, and consumer goods. The glass fiber reinforcement provides excellent dimensional stability, while the absence of halogens makes these granules suitable for applications with specific fire safety requirements.

Overall, PA6 GF30 Halogen Free Granules offer a favorable combination of mechanical properties and fire safety characteristics, making them a preferred choice in various industries.

Physical Properties of Nylon 6

It possesses excellent mechanical strength, high heat resistance, and good chemical resistance. These properties make it suitable for a wide range of applications, including automotive parts, electrical components, industrial machinery, consumer goods, and more. PA6 plastic granules derived from polyamide 6 provide manufacturers with a reliable material for injection molding processes.

At TOPONEW, as nylon 6 6 producers, we specialize in providing high-quality nylon 6 polymer derived from polyamide 6. Our granules are carefully engineered to deliver consistent performance, excellent flowability, and optimal moldability for injection molding processes.

FAQ

Polyamide 6 VS Polyamide 66

Polyamide 6, also known as nylon 6, is a thermoplastic polymer renowned for its exceptional mechanical properties, chemical resistance, and thermal stability. In contrast, polyamide 66, often referred to as nylon 66, is another member of the nylon family with even higher strength, rigidity, and thermal properties than nylon 6.

PA6 GF30 refers to Polyamide 6 (Nylon 6) material that is reinforced with 30% Glass Fiber (GF). This composite material combines the benefits of Polyamide 6 with the added strength and stiffness provided by the glass fibers.

Here are some key characteristics of PA6 GF30:

-

Improved Strength: The addition of 30% glass fibers enhances the tensile and flexural strength of the material, making it suitable for applications requiring high mechanical performance.

-

Stiffness: Glass fibers contribute to increased stiffness and rigidity of the Polyamide 6 matrix, providing dimensional stability and resistance to deformation under load.

-

Heat Resistance: PA6 GF30 generally exhibits good heat resistance compared to unreinforced Polyamide 6, making it suitable for applications where elevated temperatures are present.

-

Enhanced Wear Resistance: The presence of glass fibers can improve the wear resistance and durability of PA6 GF30, extending the lifespan of components made from this material.

PA6 GF30 is commonly utilized in various industries such as automotive, aerospace, electronics, and consumer goods where a balance of strength, stiffness, and heat resistance is required in the final product. As always, it is important to consult the technical datasheets provided by the material supplier for specific properties and guidelines on processing PA6 GF30.

Download

-

PA6 E070830WL.pdf

Download PA6 E070830WL.pdf