Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

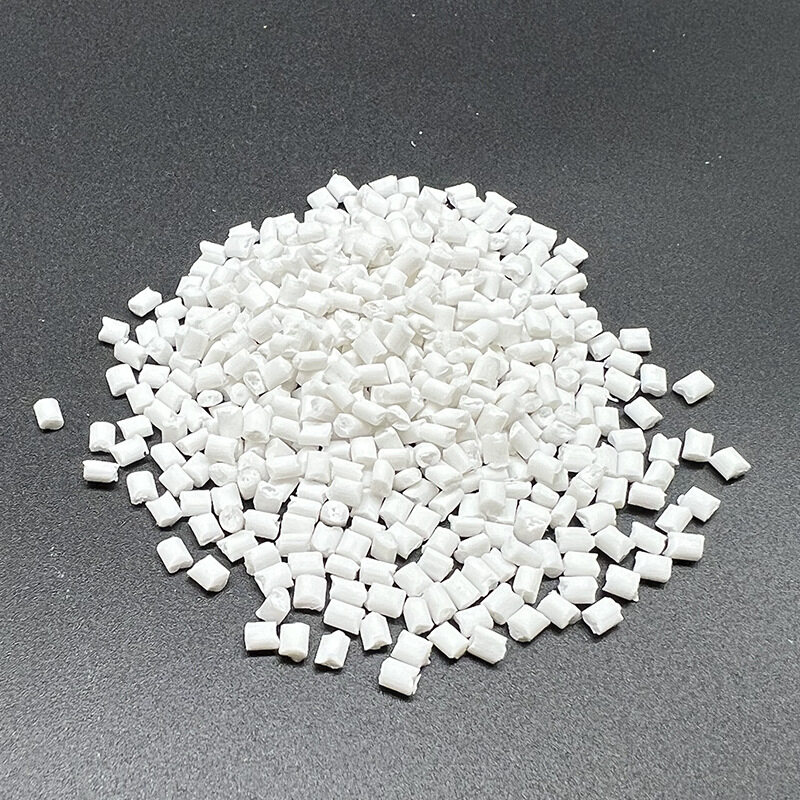

Black Masterbatch TP-1045BK

TP-1045BK Anti-floating Fiber Organic Black Masterbatch is specially designed for glass fiber reinforced engineering plastics to resist glass fiber surface exposure, and can be compatible with most engineering plastics, such as: PA6, PA66, PPA, PBT , PET, PPS, etc. .

TP-1045BK Anti-floating fiber organic black masterbatch is specially designed for glass fiber reinforced engineering plastics to resist glass fiber surface exposure, and can be compatible with most engineering plastics, such as: PA6, PA66, PPA, PBT , PET, PPS, etc. .

1. Compatible with most plastics and has a wide range of applications;

2. High temperature resistance, no fading, and 100-degree boiling resistance;

3. Anti-floating fiber, high surface gloss ;

4. There is no carbon black component, which does not affect the electrical properties of plastics.

Main Ingredient

Carrier: ternary polar copolymer

Melanin composition: organic melanin

Comparison of Properties of Organic Black and Carbon Black

|

Project |

Organic black |

Carbon black |

|

Chemical |

organic dye |

inorganic pigments |

|

Exterior |

black granule |

black granule |

|

PH Value |

6-8 |

4-11 |

|

Hue |

red to blue |

red to blue |

|

Non-polar Plastic Solubility |

insoluble |

insoluble |

|

Polar Plastic Solubility |

soluble |

insoluble |

Since organic melanin can be completely dissolved in polar polymers such as PA6, PA66, PBT, PET, etc., it achieves excellent dispersion performance in plastics, while carbon black can only rely on mechanical dispersion, and poorly dispersed carbon black will Greatly reduce the impact performance of materials; especially when engineering plastics are added with glass fiber, poorly dispersed carbon black has two disadvantages:

1. Poorly dispersed carbon black affects the degree of contact between plastic and glass fiber, which will reduce the mechanical properties of the material .

2. Carbon black can wear the coupling agent on the surface of glass fiber and reduce the bonding force between glass fiber and plastic .

And these problems are not found on the organic melanin, because it can be completely dissolved in the plastic.

|

project |

organic melanin |

carbon black |

|

Color intensity |

very good |

excellent |

|

Lightfastness |

good |

excellent |

|

UV resistance |

generally |

excellent |

|

Dispersion |

excellent |

generally |

|

Effect on the interface between glass fiber and plastic |

low |

high |

|

Abrasion of glass fiber surface coupling agent |

low |

high |

|

Impact strength |

excellent |

very good |

|

surface |

excellent |

good |

|

Luster |

excellent |

good |

|

Thermal conductivity |

low |

high |

|

Recrystallization temperature |

relatively low |

relatively high |

The use of organic black masterbatch can also provide dimensional stability and reduce shrinkage of the product, because the crystallization temperature of nylon is lower than that of carbon black, which prolongs the filling time of plastics, thereby improving the dimensional stability of the product and reducing the aftermath. shrink.

Suggested addition ratio: 1.5%-2%, can be increased or decreased according to the glass fiber content and the actual situation.

How do we develop a color masterbatch?

To develop a color masterbatch, you typically follow these steps:

-

Formulation Design: Determine the desired color shade and properties required. Select appropriate pigments or dyes to achieve the color.

-

Material Selection: Choose a carrier resin that is compatible with the base resin of the final product. The carrier resin should disperse the colorant evenly.

-

Colorant Dispersion: Mix the colorant (pigment or dye) with the carrier resin using suitable processing equipment like twin-screw extruders or kneaders to achieve uniform dispersion.

-

Processing: Melt the compounded mixture and pelletize it to form the color masterbatch pellets.

-

Testing: Perform quality control tests to ensure the color consistency, dispersion quality, and compatibility with the final product during processing.

-

Scale-up and Production: Once the color masterbatch formulation is finalized and passes all tests, scale up the production to meet the required quantities.

-

Packaging and Storage: Package the color masterbatch pellets in suitable containers and store them in a controlled environment to maintain their properties.