Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Unveiling PPA: The Specialized Engineering Plastic

Introduction:

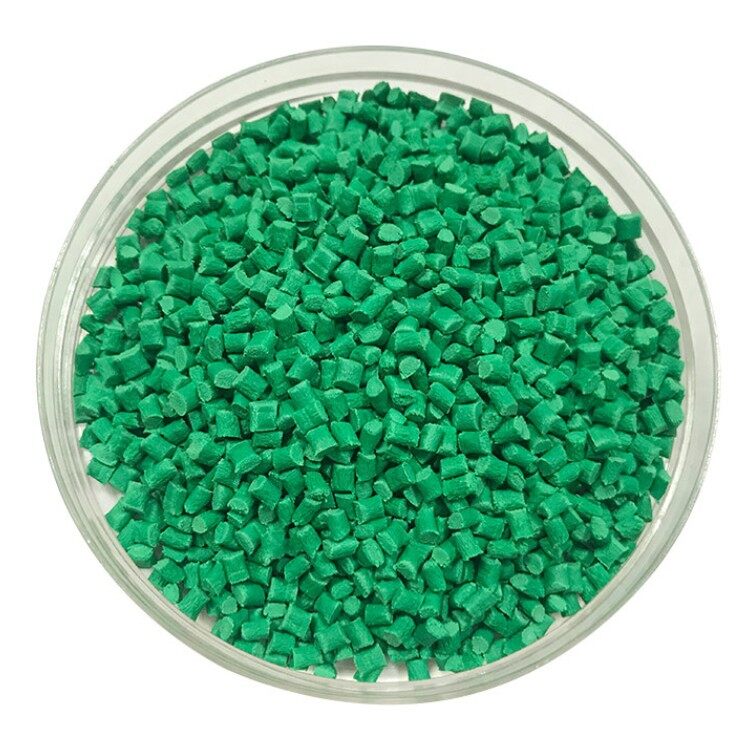

In the realm of engineering plastics, Polyphthalamide (PPA) stands out as a remarkable thermoplastic material that possesses exceptional properties. Since we could provide PPA particles white label service, this blog aims to provide an in-depth introduction to PPA, shedding light on its unique characteristics and highlighting its applications across various industries.

-

What is PPA? Polyphthalamide (PPA) is a high-performance engineering plastic that belongs to the polyamide family. It is known for its outstanding combination of mechanical strength, thermal resistance, chemical stability, and dimensional accuracy. These properties make it an attractive choice for demanding applications that require reliability and performance in challenging environments.

-

Key Features of PPA: Let's delve into some key features that make PPA a preferred choice among engineers:

a) Heat Resistance: PPA exhibits impressive heat resistance, allowing it to withstand elevated temperatures ranging up to 260°C (500°F). This characteristic makes it suitable for applications where exposure to high heat is common.

b) Mechanical Strength: PPA showcases excellent mechanical properties, including high tensile strength, impact resistance, and stiffness. This enables it to withstand heavy loads and endure dynamic stress, making it ideal for structural components.

c) Chemical Resistance: PPA demonstrates resistance to a wide range of chemicals, including acids, oils, fuels, and solvents. This property ensures its durability and longevity in harsh chemical environments.

d) Dimensional Stability: Unlike some other polyamides, PPA has low moisture absorption, which contributes to its remarkable dimensional stability over time. This attribute is crucial for maintaining precise tolerances and consistent performance in various applications.

- Applications of PPA: PPA finds extensive use in diverse industries due to its exceptional properties. Some notable applications include:

a) Automotive Industry: PPA is employed in engine components, fuel system parts, electrical connectors, and under-the-hood applications where high heat resistance, dimensional stability, and chemical resistance are vital.

b) Electrical and Electronics: PPA is utilized in electrical connectors, circuit breakers, switches, and housings for electronic devices. Its excellent electrical properties, combined with resistance to heat and chemicals, make it an ideal choice for these applications.

c) Industrial Equipment: PPA is used in pumps, valves, gears, and other industrial equipment that require reliable performance in challenging environments, including exposure to chemicals, heat, and mechanical stress.

d) Consumer Goods: PPA is found in various consumer products such as power tools, household appliances, and sporting goods. Its durability, impact resistance, and ability to withstand repeated use make it a preferred material in these applications.

Conclusion:

Polyphthalamide (PPA) stands as a remarkable specialized engineering plastic due to its impressive heat resistance, mechanical strength, chemical stability, and dimensional accuracy.

Its wide range of applications across industries highlights its versatility and reliability. As technology advances, PPA continues to evolve, opening up new possibilities for enhanced performance and innovation in the field of engineering plastics.