Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

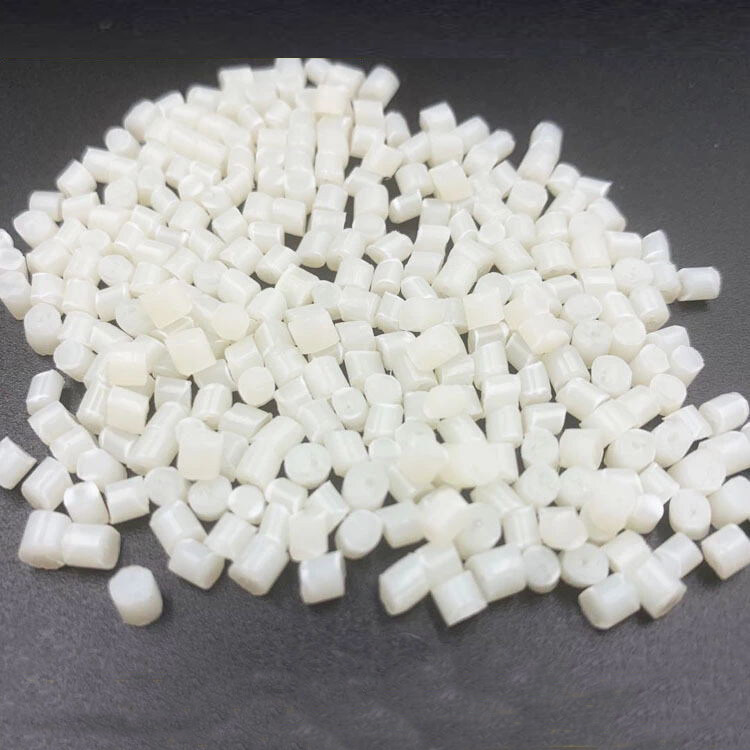

The Versatility of HIPS Pellets White Label in Product Manufacturing

High Impact Polystyrene, commonly known as HIPS, is a synthetic resin that has become a staple in the manufacturing industry due to its robustness and ease of use. When it comes to versatility and customization, HIPS pellets white label solutions stand out as a preferred choice for businesses looking to brand their products with a unique identity. In this blog post, we will explore the benefits and applications of HIPS pellets white label and how they are shaping the future of product manufacturing.

Customization and Branding with HIPS Pellets White Label

HIPS pellets white label solutions offer manufacturers the ability to customize their products to suit their branding requirements. These pellets are produced without any added color, allowing companies to incorporate their own branding colors and logos during the product manufacturing process. The term “white label” refers to the practice of rebranding a generic product with a company’s own label, and HIPS pellets white label makes this process seamless for a wide range of industries.

Material Properties and Advantages

HIPS pellets white label are known for their high impact strength, which makes them an excellent choice for products that require durability and resistance to wear and tear. The material’s rigidity, combined with its ability to be easily molded and extruded, allows for the creation of intricate designs and shapes. Additionally, HIPS pellets white label possess good dimensional stability and are resistant to acids, alkalis, and some oils, making them suitable for various environmental conditions.

Applications in Electronics and Appliances

One of the primary uses of HIPS pellets white label is in the electronics and appliance sectors. The material’s insulating properties and structural integrity make it ideal for housing electronic components, such as computer and TV casings. Manufacturers can easily apply their branding to these products, creating a consistent and recognizable appearance across their product lines.

Packaging Solutions with HIPS Pellets White Label

The packaging industry greatly benefits from the use of HIPS pellets white label. The material’s impact resistance and rigidity are essential for protecting goods during transport and storage. Custom packaging designs with company branding can be produced, providing a professional look while ensuring product safety.

Toys and Consumer Goods Manufacturing

HIPS pellets white label also find extensive use in the production of toys and various consumer goods. The safety and non-toxic nature of HIPS make it a suitable material for children’s products. Manufacturers can create a diverse range of items, from action figures to household containers, all while incorporating their unique branding and color schemes.

Environmental Considerations and Recycling

In today’s eco-conscious market, the recyclability of HIPS pellets white label is a significant advantage. The material can be recycled and repurposed, reducing waste and promoting sustainable manufacturing practices. Companies can highlight their commitment to the environment by using recycled HIPS pellets white label in their products.

Conclusion

HIPS pellets white label solutions offer manufacturers the flexibility to create customized, branded products with a material that is durable, versatile, and environmentally friendly. The wide range of applications, from electronics to packaging and toys, demonstrates the material’s adaptability and its importance in the manufacturing industry. As businesses continue to seek innovative ways to differentiate their products, HIPS pellets white label will undoubtedly remain a key component in the development of high-quality, branded merchandise. With the added benefit of recyclability, HIPS pellets white label not only meet the demands of modern manufacturing but also align with the growing trend towards sustainability.