Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

The Science of Aging: How to Enhance Nylon's Durability

Introduction:

Aging is a natural process that affects various materials, including polymers. High polymer materials, such as nylon, experience changes in their structure, physical state, and performance when exposed to external factors such as heat, light, oxygen, moisture, chemicals, and microorganisms. This phenomenon, known as aging, leads to a decline in the material's properties and may render it unusable. In this blog, we will explore what aging is and discuss methods to enhance nylon materials' resistance to aging.

Understanding Aging:

Aging in high polymer materials can manifest in several ways, including changes in appearance, physical properties, mechanical properties, and electrical properties. Materials may develop stains, spots, cracks, or discoloration. Their mass, dimensions, thermal resistance, and cold resistance may undergo alterations. Furthermore, their mechanical strength, such as tensile, bending, and compression properties, may decline significantly. Electrical characteristics, such as insulation resistance, dielectric loss, and breakdown voltage, can also be affected.

Importance of Enhancing Resistance to Aging:

High polymer materials play a vital role in various applications. However, when these materials experience aging and lose their properties, it can result in economic loss and even environmental damage or accidents. Thus, it becomes crucial to replace aged polymer products before they become unusable. With the principles of energy-saving, low carbon, and ecological development in mind, ensuring the reliability and durability of polymer materials has become a significant focus.

Enhancing Nylon's Resistance to Aging:

Nylon, specifically PA6 and PA66, is known for its lightweight, high toughness, electrical insulation, and thermal insulation properties. It finds extensive use in applications such as electronic appliances, machinery casings, automotive parts, and more. However, nylon used in electronic devices requires not only excellent mechanical strength but also minimal changes in appearance and color after aging. This is particularly important for products with strict aesthetic requirements, especially light-colored nylon products that could affect the performance of electronic devices.

Factors Affecting Nylon Aging:

Nylon materials used indoors may experience elevated temperatures, making heat one of the primary factors in their aging process. Additionally, the presence of oxygen in the surrounding environment accelerates the aging of nylon. Therefore, taking anti-aging measures for nylon, such as PA6 and PA66 , is necessary.

Methods to Enhance Nylon's Resistance to Aging:

There are several effective methods to enhance nylon's resistance to aging:

1.Adding antioxidants: Adding antioxidants improves nylon's resistance to heat aging and significantly extends its lifespan. Commonly used antioxidants include copper stabilizers, amine and hindered phenol antioxidants, and hydrogen peroxide decomposers.

2.Blending modification: Blending modifiers, such as POE-g-MAH elastomers, can improve nylon's resistance to thermal aging to a certain extent.

3.Selection of anti-aging agents: Different anti-aging systems have varying anti-aging effects on nylon. According to data and experiments, the anti-aging effect is as follows: copper salt antioxidants > 1098 + 626 antioxidant system > 1098 antioxidant system > 1010 + 626 antioxidant system. Black reinforced nylon materials, due to the excellent UV absorption of carbon black, show higher resistance to aging compared to colored reinforced nylon.

4.Synergistic effect: The combination of copper salt antioxidants and antioxidant 1098, as well as some other combinations, has a synergistic effect in enhancing nylon's resistance to thermal aging.

Conclusion:

Aging is a common issue faced by high polymer materials like nylon. However, by adding antioxidants, employing blending modification, and selecting appropriate anti-aging agents, nylon's resistance to aging can be significantly enhanced. These measures allow us to maximize the reliability and durability of nylon materials, conforming to the principles of energy-saving, low carbon, and ecological development. At TOPONEW, we are committed to providing high-performance and long-lasting polymer materials to meet the ever-growing demands of various industries.

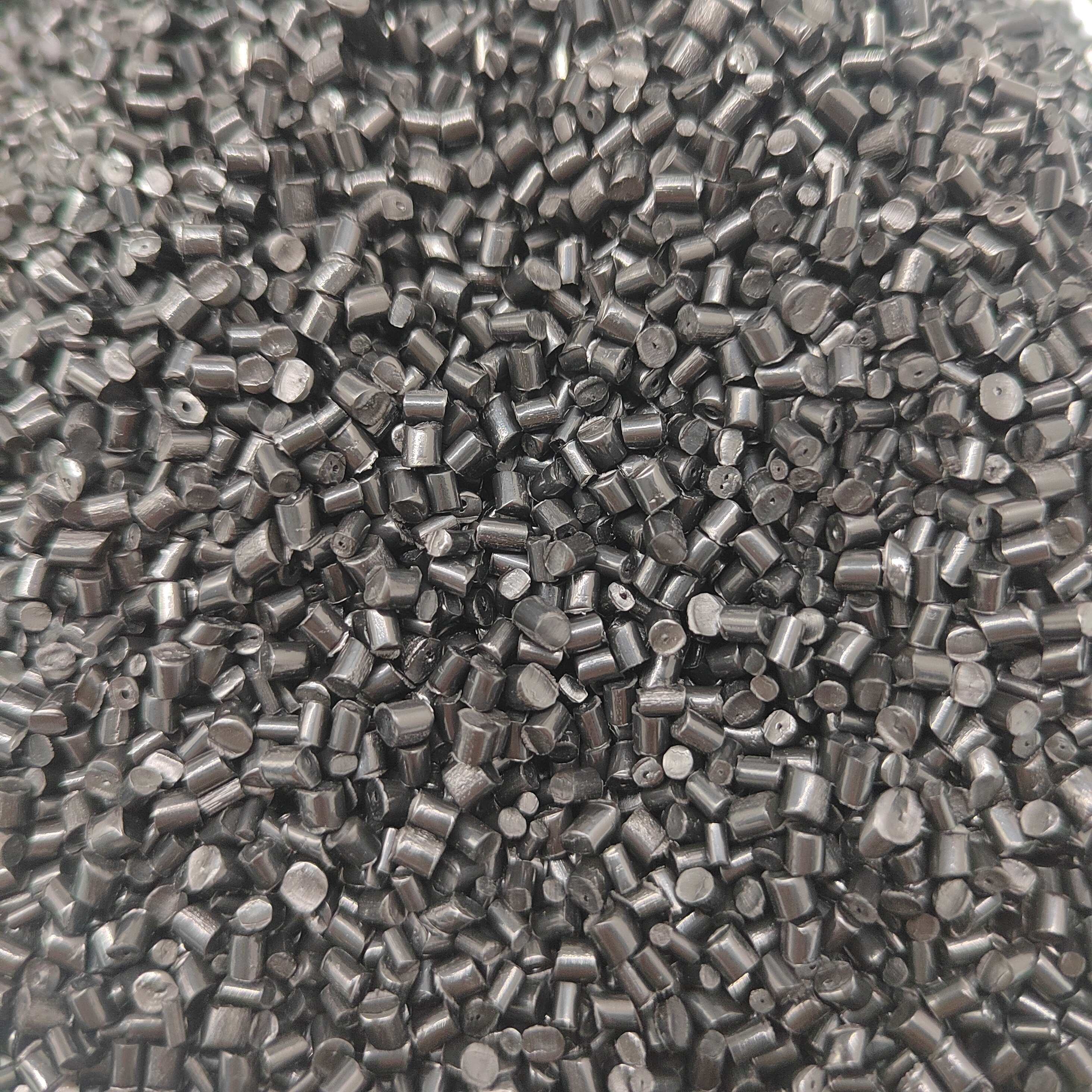

Related Product:

PA6 GF15

https://www.toponew.com/products/pa6-compound/PA6-E0715

PA66 GF35

https://www.toponew.com/products/pa66-compound/pa66-gf35-f0735