Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

The Impact of Fiberglass Content on the Performance of Plastic Granules

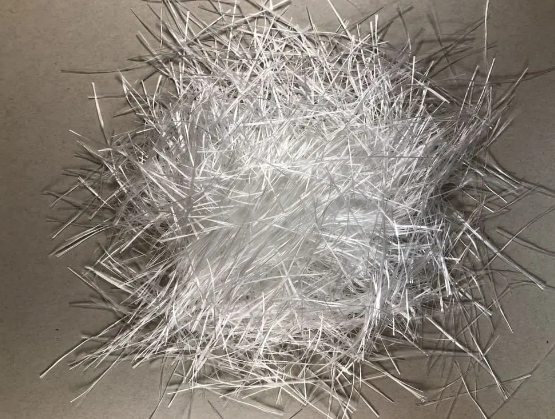

Fiberglass, also known as glass fiber, is a type of reinforced material widely used in various industries. When added to plastic granules, it can significantly enhance the strength, stiffness, and thermal properties of the resulting plastic products.

Firstly, the addition of fiberglass to plastic granules improves the mechanical properties of the materials. The high tensile strength and low weight characteristics of fiberglass fibers reinforce the plastic matrix, increasing its overall tensile strength, flexural strength, and impact resistance. This makes the plastic products more durable and capable of withstanding higher loads and impacts.

Secondly, the presence of fiberglass in plastic granules enhances the thermal properties of the resulting materials. Fiberglass has excellent thermal stability and resistance to high temperatures, which will transfer to the plastic matrix. As a result, plastic products with fiberglass content have improved heat resistance, flame retardancy, and thermal insulation properties. This makes them suitable for various applications in the automotive, aerospace, and construction industries, where exposure to high temperatures is common.

Additionally, increased fiberglass content in plastic granules can improve the dimensional stability of the resulting plastic products. Fiberglass fibers distribute evenly within the plastic matrix, preventing shrinkage and deformation during the cooling and solidification process. This results in products with higher dimensional accuracy and reduced warping or distortion.

However, it is worth noting that excessive fiberglass content can also have adverse effects on the performance of plastic granules. Too high of a fiberglass content can reduce the ductility and impact resistance of the plastic matrix, making it more brittle. Furthermore, the addition of fiberglass may increase the cost of manufacturing plastic products due to the higher material and processing costs associated with fiberglass-reinforced plastic.

In conclusion, the addition of fiberglass to plastic granules has a significant impact on the performance of the resulting plastic products. Proper adjustment of the fiberglass content allows for the improvement of mechanical strength, thermal properties, and dimensional stability. However, careful consideration should be given to avoid exceeding the optimal fiberglass content, which may negatively affect the plastic's overall properties.