Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Exploring High Impact Polystyrene (HIPS): Properties, Production, and Diverse Applications

Introduction:

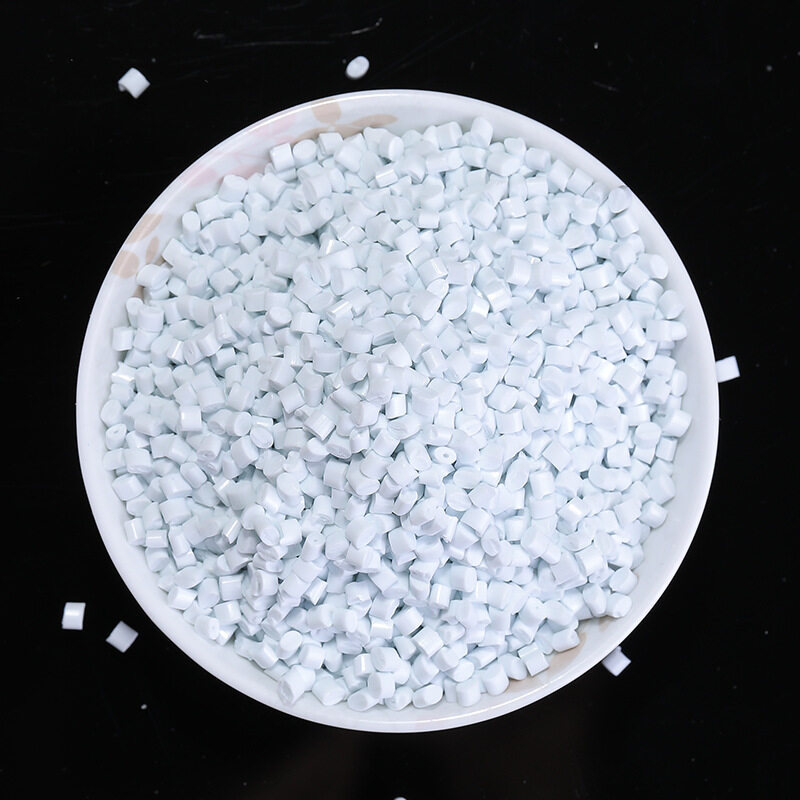

High Impact Polystyrene, commonly known as HIPS, is a thermoplastic material made from styrene-butadiene copolymers. It comprises a two-phase system consisting of a rubbery phase and a continuous polystyrene phase, which has evolved into a significant polymer commodity worldwide. This versatile product offers a wide range of applications due to its broad spectrum of impact resistance and processing capabilities. It finds extensive use in automotive, appliances, electronics, furniture, household goods, telecommunications, computers, disposable items, pharmaceuticals, packaging, and entertainment markets.

Polystyrene is one of the oldest industrially produced thermoplastic polymers and is widely used in various applications. While its advantages include brightness, purity, ease of processing, rigidity, dimensional stability, and transparency due to its non-crystalline nature, its low impact strength has historically limited its applications.

High Impact Polystyrene involves grafting small amounts of polybutadiene onto a polystyrene base, creating a "sea-island structure" where the matrix is plastic and the dispersed phase is rubber.

It exhibits several characteristics:

Odorless, tasteless, hard material with excellent dimensional stability after molding.

Excellent high dielectric insulation properties.

Low water absorption material with high resistance to quality degradation.

Good glossiness and ease of coating.

Production Methods:

HIPS is produced using two basic manufacturing processes: batch process and continuous process. Both processes typically begin with prepolymerization. After prepolymerization, the batch process continues polymerization in a suspension form, while the continuous process proceeds in a solution form. Hence, the batch process is also known as the bulk suspension process, and the continuous process is known as the solution process.

Properties:

HIPS offers dimensional stability similar to General Purpose Polystyrene (GPPS) but with improved impact strength and rigidity. Its relative density ranges from 1.04 to 1.06, with a heat distortion temperature of 70 to 84°C. Its tensile strength is approximately 15 to 30 MPa, with an elongation at break of 35 to 60%. Its properties exhibit some resemblance to elastomeric toughened systems, with creep increasing with decreasing temperature and increasing strain rate. The creep behavior of HIPS is highly dependent on the average molecular weight (Mw). Its flexural strength ranges from 29.4 to 50 MPa, impact strength from 0.09 to 0.16 N/M, Vicat softening point from 84 to 100°C, and melt index from 2 to 9 g/10min. The heat resistance of HIPS components depends on their shape, production conditions, heat source type, heating duration, and HIPS grade.

In contact with water, alkalis, and dilute inorganic acids, HIPS properties remain unaffected. It may swell in some organic solvents and dissolve in others, depending on the differences in dissolution parameters between the continuous phase and the solvent phase. HIPS is particularly prone to degradation when exposed to chlorinated hydrocarbons and aromatic hydrocarbons.

Reasons for Impact Resistance:

Impact-resistant polystyrene is produced by incorporating polybutadiene rubber particles into polystyrene. This product adds micrometer-scale rubber particles and connects polystyrene and rubber particles through grafting. When subjected to impact, the stress at the tip of crack propagation is released by the relatively soft rubber particles. As a result, crack propagation is impeded, leading to improved impact resistance.

Applications:

Due to its ease of manufacturing and low cost, HIPS is widely used in various utensils and industries. Major industrial and market sectors include packaging, disposable items, utensils and consumer appliances, toys and recreational goods, construction products, and decorations. The largest single application of HIPS is in packaging, especially in the food industry, accounting for over 30% of global consumption.