Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Offer Technical Support and Customized Solutions

The company is committed to creating new and improved plastic materials to meet the evolving demands of the market.

Detailed Explanation of Nylon Injection Molding Process Adjustment

Nylon is a widely used thermoplastic material, known for its excellent mechanical strength, wear resistance, and chemical resistance, making it widely applied in various industrial fields. During the injection molding process, the adjustment of nylon material is crucial as it directly affects the quality and production efficiency of the products. The following is a detailed analysis of the adjustment of nylon injection molding process.

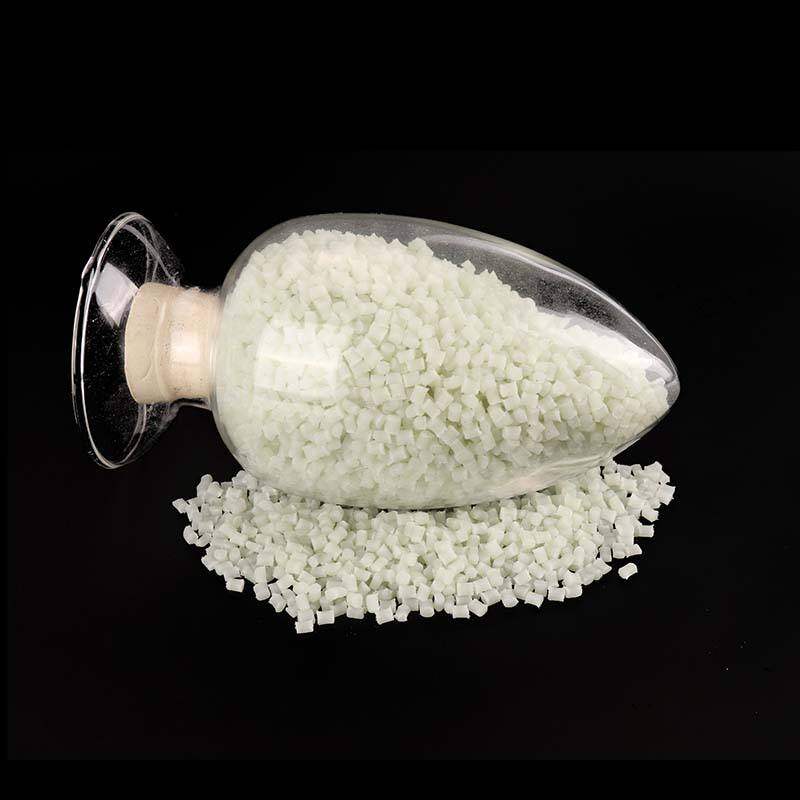

Material Preparation and Pre-treatmentMaterial Selection: Choose the appropriate type of nylon according to the product requirements, such as Nylon 6, Nylon 66, Nylon 1010, etc. Different types of nylon have differences in performance, so selection should be based on factors such as the required strength, hardness, heat resistance, chemical resistance, etc. of the product.

Pre-treatment: Nylon material should undergo sufficient drying treatment before injection molding to remove moisture from the material. Excessive moisture content can cause problems such as bubbles and deformation during the injection molding process. The drying temperature and time should be determined according to the specific material, generally recommended at 80-100℃ for 24 hours.

Injection Machine Selection and SetupInjection Machine Selection: Choose a suitable injection molding machine based on factors such as product size, complexity of structure, production volume, etc. The tonnage, shot volume, injection pressure, and other parameters of the injection molding machine should match the product requirements.

Injection Machine Setup: On the operation interface of the injection molding machine, parameters such as injection speed, injection pressure, holding pressure, holding time, cooling time, etc., need to be set. The adjustment of these parameters will directly affect the molding quality and production efficiency of the products.

Adjustment and Optimization of Process ParametersInjection Speed: Excessive injection speed may cause problems such as voids and flow marks inside the product, while too slow may result in defects such as shrinkage and sink marks on the product surface. Therefore, the appropriate injection speed should be selected based on the product structure and material properties.

Injection Pressure: The magnitude of injection pressure directly affects the filling speed and density of the plastic in the mold. Too low injection pressure may result in insufficient filling, while too high may cause product deformation or flash. The adjustment of injection pressure should be combined with injection speed and mold structure.

Holding Pressure and Time: The main purpose of the holding phase is to compensate for the shrinkage of the plastic in the mold, ensuring the stability of product dimensions and internal quality. Inadequate holding pressure may result in shrinkage of the product, while excessive holding time may cause product deformation. Therefore, reasonable holding pressure and time should be set based on the size and structure of the product.

Cooling Time: The length of cooling time directly affects the molding cycle and production efficiency of the product. Too short cooling time may result in incomplete solidification of the product's interior, while too long may reduce production efficiency. Therefore, reasonable cooling time should be set based on factors such as product thickness, material thermal conductivity, and mold temperature.

Mold Design and AdjustmentMold Temperature: Mold temperature has a significant impact on the injection molding process of nylon material. Excessive mold temperature may result in rough surface, unstable dimensions, while too low mold temperature may lead to insufficient filling or internal stress. Therefore, reasonable mold temperature should be set according to product requirements and material properties.

Mold Structure: The design of the mold structure should consider factors such as the structural characteristics of the product, dimensional accuracy, and demolding requirements. A reasonable mold structure can reduce product defects and improve production efficiency.

Summary and RecommendationsAdjusting the injection molding process of nylon material is a complex and meticulous process, requiring comprehensive consideration of factors such as material properties, injection molding machine parameters, mold structure, and production environment. In practical operation, multiple trials and parameter adjustments should be conducted based on product requirements and production conditions to find the optimal combination of process parameters. Additionally, regular maintenance and upkeep of injection molding equipment and molds should be carried out to ensure the normal operation of equipment and stable production of products.